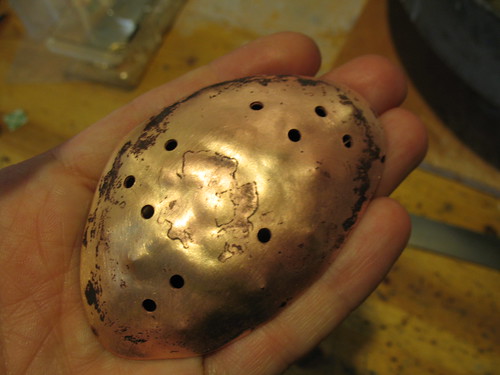

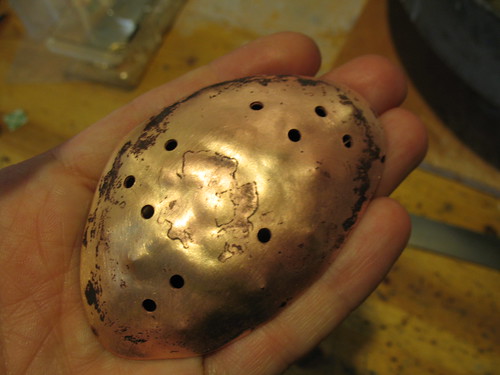

I mentioned yesterday that I'm working on some new designs for my upcoming show. Here is one of the new pieces. I made this shape on Monday and had lots of fun working on it. I can't yet use my hydraulic press for a piece this big, I don't have a large enough piece of urethane. So I cut the shape and used a dapping punch to form it. It isn't as smooth as it would have been if it was formed in the press, but I don't mind some texture. In fact I have a list of tools and supplies that I want that will help me create lots more texture in my work:

Rolling Mill

Pitch and Pitch Bowl

Etching Supplies

Rolling Mill

Pitch and Pitch Bowl

Etching Supplies

I'm really happy with the shape that I came up with. It is reminiscent of the pebbles that I use in my jewelry. I drilled the holes and prepped the piece for enameling. I'm just getting back into enameling and I have this beehive kiln. I was only able to get it to work when the piece was laid directly on the elements for counter enameling. When it was up on a trivet it didn't even start to fuse the enamel. Perhaps this kiln only works well for smaller pieces? If anyone has experience with one of these I would appreciate some tips!

I couldn't lay the piece back on the kiln floor after it was counter enameled, so I torched fired it for the other side. Here it is underfired. The white turned gray which I read online could be caused by an Acetylene /air torch, which is what I use. I don't mind the gray though and think it makes it look more pebble like, so I consider it a happy accident.

This is where I'm going with this pendant. The gemstones will somehow be connected to the top of the enameled piece. I have several ideas for how to do this and may need to do some sample pieces to see which works best.

Hm, I see some rings in my future, no point in just doing samples that I don't use for anything! I'm also not sure yet how this whole piece will be set, I have to work on that today.

Torch firing enamel tips are welcome too. I am new to torch firing and not even sure if it is supposed to work on a piece this large. I'm thinking I need to build a little surround of soldering bricks to hold the heat in. Does that sound useful?

Add to tool wish list:

Kiln

1 comment:

hi Ashley, thank you for posting your working process, I always find it interesting to see how fellow metalsmith go about their work.

Post a Comment